The Institute for Applied Plastics Research (iRAP) at HEIA-FR developed over the years an extensive expertise and dedicated infrastructure for ceramic injection molding (CIM), a cutting-edge technique with multiple applications.

Ceramic Injection Molding (CIM) is a cutting-edge technique that enables production of net-shaped parts, through the injection of ceramic powders and binders into a mold. This process offers numerous advantages, allowing the creation of shapes that would be too difficult or expensive to manufacture using traditional methods. It is a complex process that requires extensive expertise and specialized facilities.

The Institute for Applied Plastics Research (iRAP), part of the School of Engineering and Architecture of Fribourg (HEIA-FR), has developed this extensive expertise and dedicated infrastructure for ceramic injection molding over the years. Working closely with industrial partners, iRAP drives innovation in both product development and manufacturing processes. Through several research projects conducted with companies, the Institute explores the feasibility and technical limits of the CIM process.

CIM: A State-of-the-Art Process for an Exceptional Material

Technical ceramics are ideal for industrial applications where durability and precise functionality are essential. They offer a unique combination of properties: extreme hardness, high wear resistance, excellent mechanical strength, outstanding electrical insulation, strong resistance to corrosion and to extreme temperatures. For biocompatible ceramics, this process is also suitable for the manufacture of medical devices and implants.

To ensure high-quality results, every step of the process—feedstock preparation, part and mold design, injection, debinding and sintering —must be precisely controlled and expertly mastered. Through numerous projects, iRAP has continuously pushed the boundaries of CIM, enabling the production of high-performance components at medium and large scales for cutting-edge applications, ranging from dental implants to neurostimulator housings.

Applied Research in Action: Selected Projects

In partnership with Straumann, iRAP worked on the Innosuisse project Enhancing Ceramic Dental Implants. The goal was to improve the density and mechanical strength of the implants. To achieve this, the team developed a more stable process, integrating vibrations into the mold, which enables up to 25% higher mechanical strength. The project is a success, and the newly developed manufacturing process has been patented.

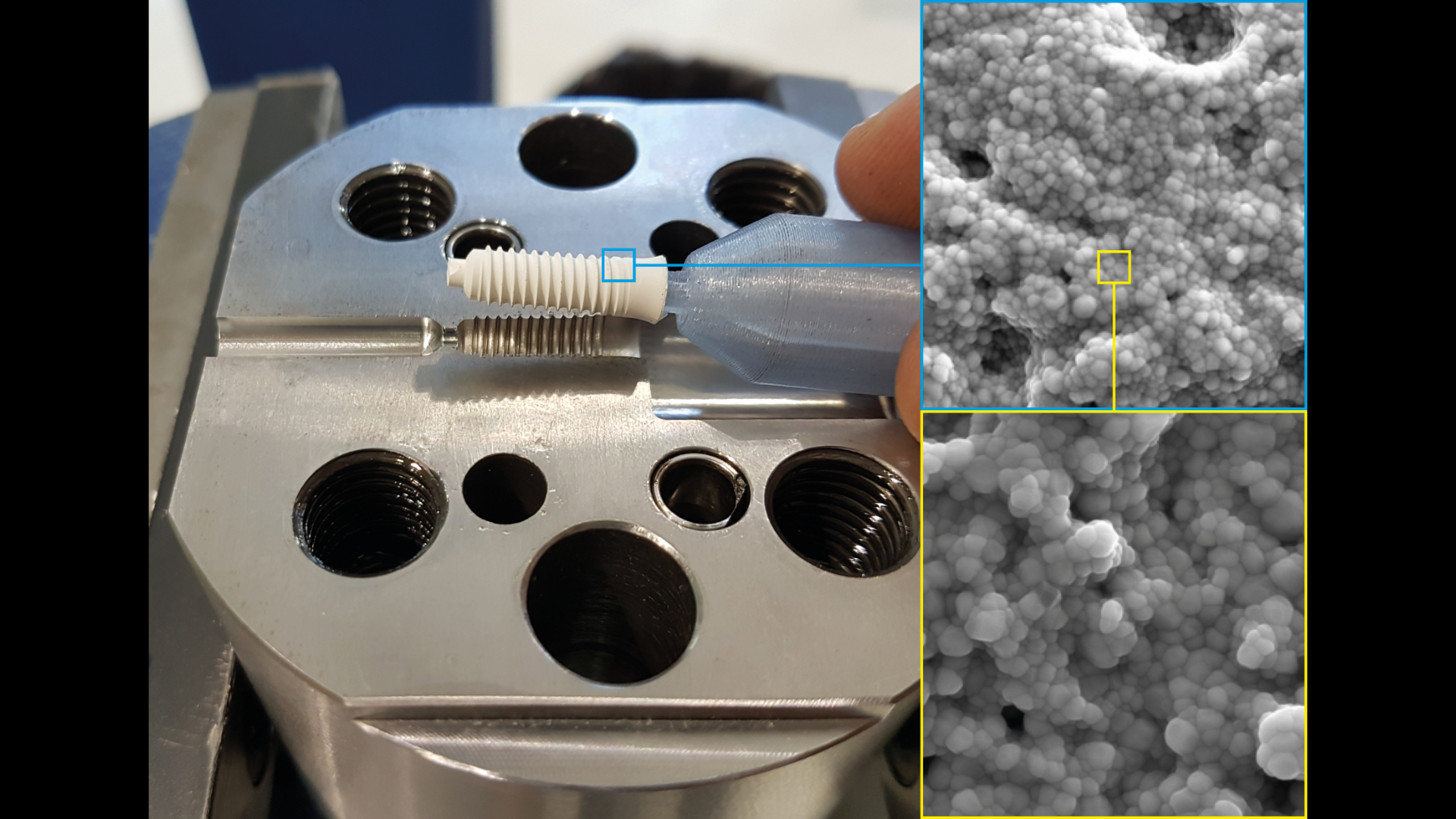

Further collaborating with Straumann, a second Innosuisse project was launched: Net-Shaped Functional Microstructures. While CIM is a net-shape process, integrating functional dental microstructures directly into ceramic implants previously required an additional post-processing step. To address this challenge, iRAP developed a solution: replicating the mold to integrate these microstructures into the implants in a single step. Tests on the osseointegrative functionality are successful, and a patent application was filed for both the structures and the net-shape process.

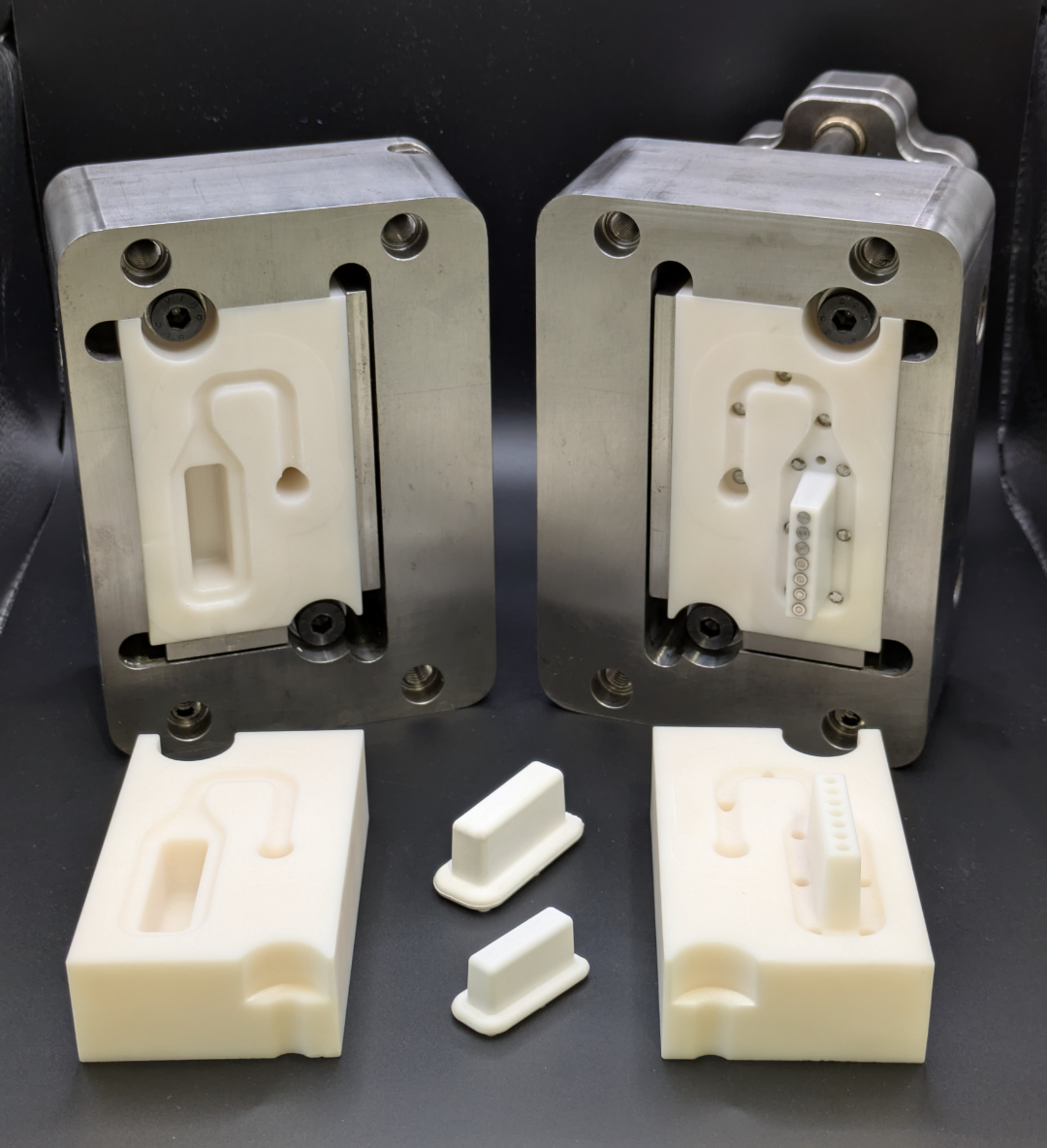

For this third project, Additive Manufacturing of CIM Molds, the goal was to develop a cost-effective prototyping technology for ceramic parts, with quality close to mass production. Indeed, prototyping is a decisive phase in production but carries risks when scaling up. To address this challenge, the institute designed molds (figure beside) that can be created in less than one week at a low cost (under CHF 1,000). With these molds, iRAP can now offer prototyping and small-scale production (fewer than 100 parts), closely matching industrial-quality results.

About iRAP

With its unique know-how, iRAP supports the entire development cycle - from concept to industrialization - directly at the partner's site.

Find out more: iRAP - Institute of Applied Plastics Research - HEIA-FR