In 2019, Dynatec, a company with expertise in high-precision machining, has embarked on an ambitious project: to develop a biobased composite material and combine it with a digital twin to optimize the implementation process and thus gain in agility. The project was carried out in collaboration with HEIG-VD, and received Innosuisse funding with the help of Alliance.

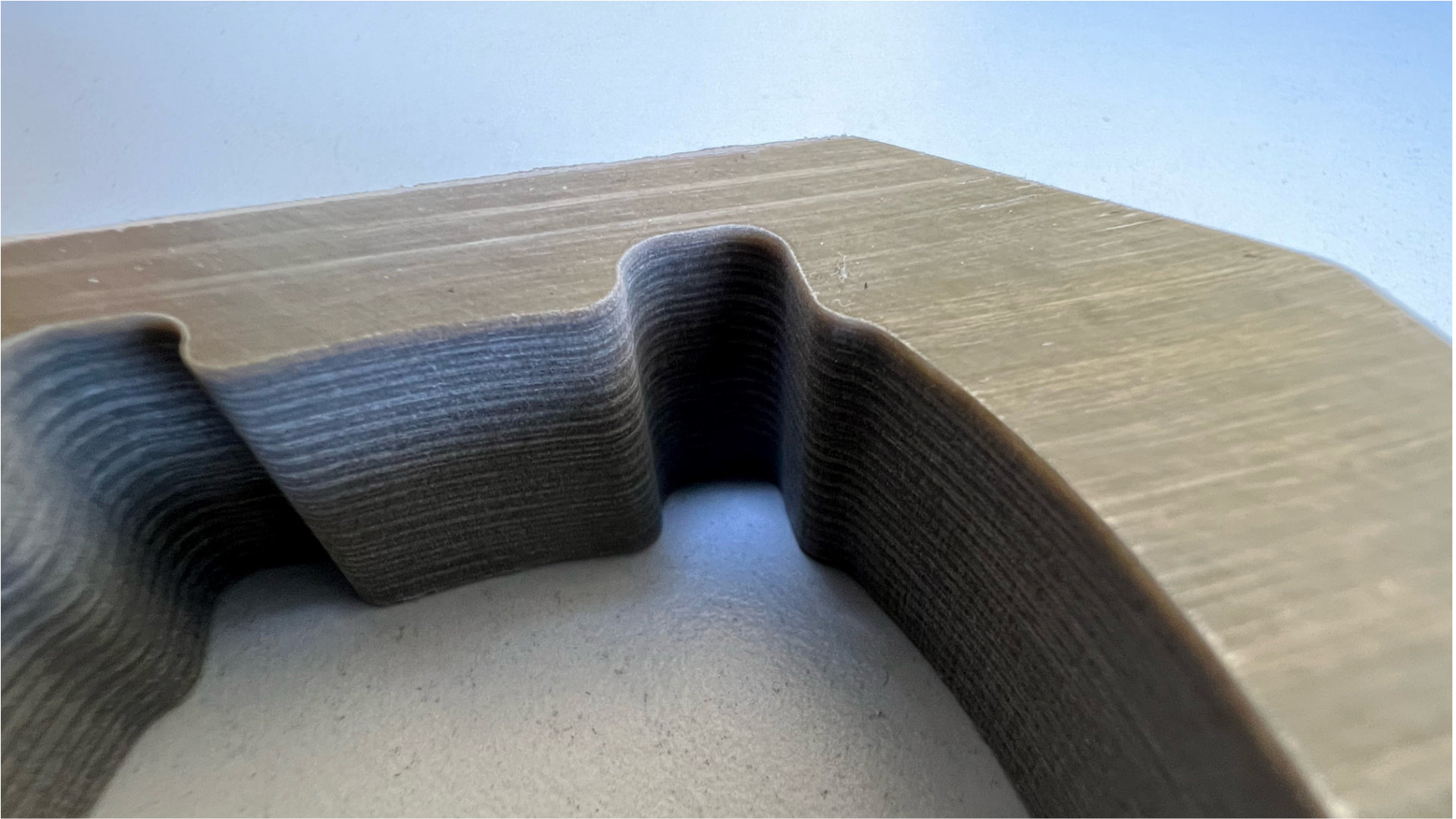

For machining biocomposite parts, Dynatec uses prepregs consisting of a matrix (resin or polymer) impregnated with a fiber reinforcement. These prepregs take the form of extremely thin sheets, which are then compressed to form blocks of material. The parts created from these prepregs have the advantage of being highly resistant and lightweight, and are used in a wide range of fields including watchmaking, aviation and medicine.

Born of a discussion with engineering schools, the project saw the light of day in 2019. The aim is twofold: to design a base material derived from bio-based materials, and to couple this development with a digital twin that can predict the result of pressing without performing physical or mechanical tests. While Dynatec had the in-house skills to develop the material, they needed an academic partner to create the digital twin. A member of the association since 1999, it was natural that Jean-Michel Meyer, Dynatec's Director of Sales and Logistics, should turn to Alliance for support.

Pascale Van Landuyt, innovation mentor in innovation at Alliance, followed the project from the outset. With her help, HEIG-VD's COMATEC institute, headed by Professor Joël Cugnoni, was identified for its expertise in composites processing, and the project obtained Innosuisse funding. This was a huge help for us," explains Jean-Michel Meyer. These Inosuisse projects are always complicated. We saved an enormous amount of time thanks to Pascale Van Landuyt. She knew exactly how to put together the file and the business plan. We benefited from really relevant support.

For the biocomposite design, Dynatec opted for a 100% natural matrix to initiate the process. For the reinforcement, the choice fell on rock fiber, combining good fiber length and a lower degree of transformation. In parallel, HEIG-VD worked on the digital twin, which will enable Dynatec to run simulations for their customers, with a plausibility rate of around 85%, thus saving the time and resources usually required for physical and mechanical testing.

Today, the project is in the process of transferring activity and knowledge to HEIG-VD. The latter will transfer the digital twin so that Dynatec can use it autonomously. The final stages of the project will then be carried out internally by Dynatec. Thanks to this project, the company will gain greater agility in the production of biocomposites, thereby increasing its market share for this type of material.

If we have another idea for a project with the academic sector and the help of Alliance, I'll start again tomorrow. This project has been very rewarding for us, but also for the academic partner. We learned a lot about the materials we use, and we had a real exchange with HEIG-VD.